Flash Point Test Procedure:

Procedure: Solvent-type products (those that form two distinct layers,

as seen in the previous demonstration) will often have a flash point that

is low enough to be dangerous. If the flash point (sometimes even the fire

point) is at, or below room temperature, that fact can be demonstrated as

follows:

- Pour a small amount of the competing

product into one of the metal dishes.

- Keep another metal dish handy to smother

the fire, should the product ignite, during the next step.

- Pass a lighted match slowly accross the

surface, about ¼ inch above the product.

- Repeat steps 1 & 2 with Alken Even-Flo® to show

that our product will not ignite.

Sludge Dissolving Test Procedure:

- Place a small dab of sludge in the center

of two metal dishes

- Add 3 drops of water to both

- Cover the whole with a heavy non-detergent

motor oil (SAE 30 or equivalent). This simulates conditions at the bottom

of an oil-tank. The motor oil allows the action to be visible.

- Add 2 droppers of competitive treatment

to one dish and 2 droppers of Alken

Even-Flo® to the other.

| The surfactants in Alken

Even-Flo® will begin to attack the sludge and emulsify the water, while

the competitive treatment will show little action other than a slight solubilization

of the sludge. |

- At times, it may be advantageous to hasten

the action by slightly warming the dishes with a lighted match held under

them Be careful using a competing product with a low flash point.

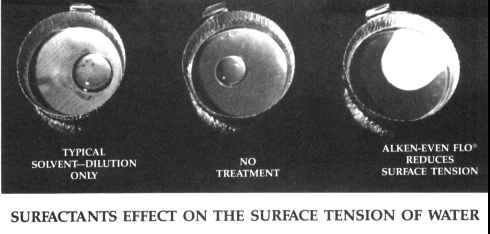

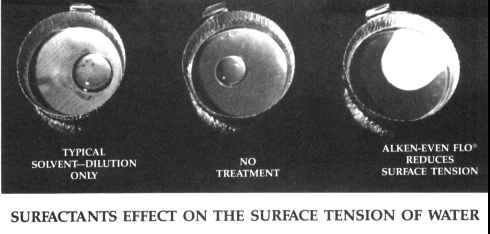

Surface Tension Test Procedure:

- Place a drop of water, about ¼ inch

in diameter, in each of two aluminum weighing dishes.

- To one of these dishes, add a drop of the

competitive product, to the other add a drop of Alken Even-Flo®. Add the products very gently by just bringing

the drop of treatment into contact with the edge of the water drop.

- Most competitive products will simply surround

the water drop and slightly increase its size. Alken Even-Flo® on the other hand, will reduce the surface tension

of the water to such an extent that it will immediately spread over the

entire surface of the dish.

|